شرکت سینی و نردبان کابل الوند تولید کننده انواع سینی کابل ، نردبان کابل و ترانکینگ در ابعاد و ضخامت های مختلف

سینــی کابل

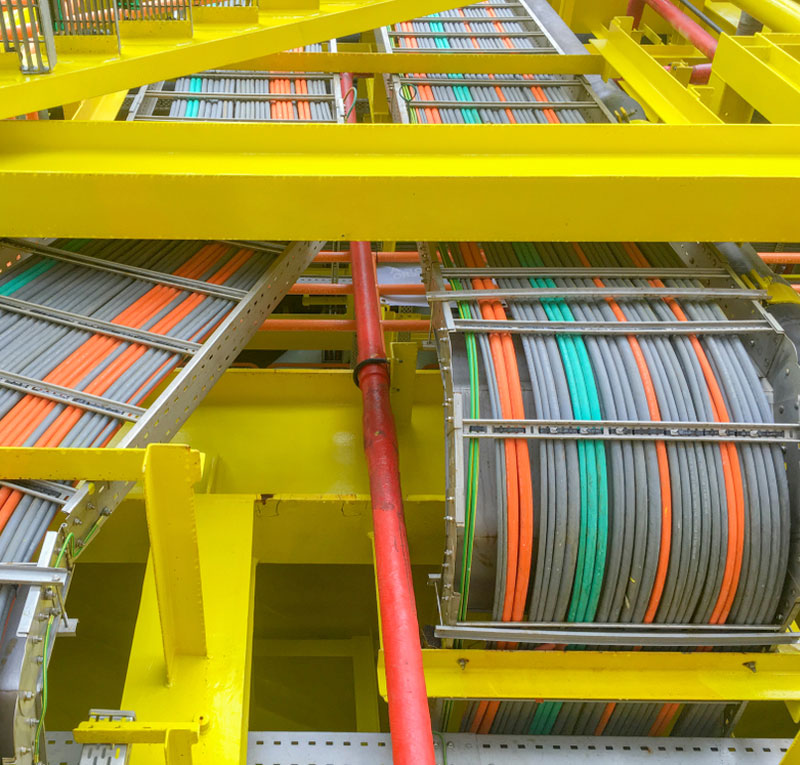

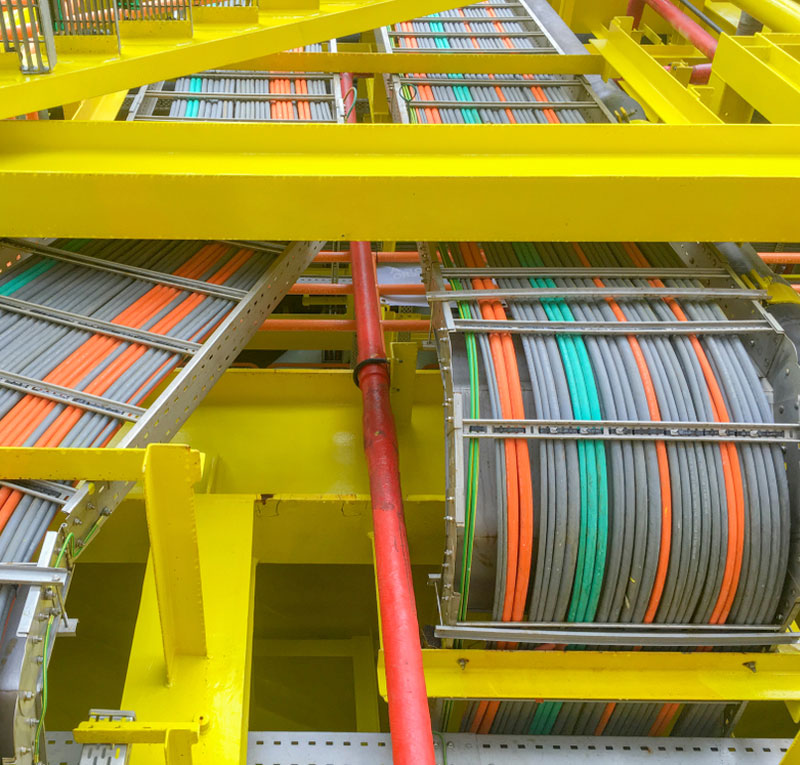

سینی های کابل سازه های ساخته شده از ورق فولادی ، پی وی سی و یا جی آر پی هستند که برای پشتیبانی و عبور کابل ها برای مصارف عمومی و اختصاصی استفاده می شوند

نردبـان کابل

سینی های نردبان سازه های فلزی پیش ساخته هستند که از دو ریل جانبی تشکیل شده اند که توسط پله های نردبان که بصورت عرضی بر روی این دو ریل جاگذاری میشود به همدیگر متصل شده و تشکیل یک مسیر مطمئن برای سیستم کابل کشی را میدهد

ترانکینگ

ترانکینگ ها محفظه های در بسته ای هستند که جهت توزیع سیستم های برق نرمال اضطراری شبکه های کامپیوتری تلفن سانترال سیستم های صوتی اعلام حریق و … استفاده میگردد و جایگزین سیستم سنتی لوله کشی برق شده است

دربــاره شــرکت

سینی و نردبان کابل الوند

سینی و نردبان کابل الوند تولید کننده انواع "سینی کابل" ، "نردبان کابل" در ابعاد و ضخامتهای مختلف ، "سینی کابل سبدی" (وایر مش) ، "ترانکینگهای دفنی" ، "ساپورتهای" نگهدارنده سینی کابل و نردبان کابل بصورت "آویز" (سقفی) ، "دیواری" و "زمینی" ، "جعبه های تقسیم آلومینیومی" و " پلی کربنات" ، "انواع براکت" مورد نیاز در پروژه های صنعتی و ساختمانی و..... میباشد .

این شرکت به جهت استفاده از استانداردهای روز دنیا نظیر

- IPS

- DIN

- ASTM

- IEC

در بخش تولید ، فنی و طراحی توانسته است تولیدات خود را متناسب با نیاز پروژه ها در سطح کشور آماده نموده و در این مدت به دستاوردها و نوآوری های خوبی دست پیدا کرده است

شرکت سینی و نردبان کابل الوند در مدت زمان فعالیت خود، تنوع محصولات و تولیدات خود را در بخش های مختلف و مورد نیاز صنعت برق و با در نظر گرفتن توان تولیدی و فنی خود گسترش داده است

برخی از استانداردهای اخذ شده توسط شرکت سینی و نردبان کابل الوند

برخی از تولیدات شرکت سینی و نردبان کابل الوند

- انواع سینی کابل و نردبان کابلساخته شده با ورق گالوانیزه ( فابریک ) ، ورق روغنی همراه با آبکاری گالوانیزه گرم ، ورق استیل و آلومینیوم به همراه کلیه اتصالات

- انواع ترانکینگ دفنی ساخته شده با ورق گالوانیزه (فابریک) ، ورق روغنی همراه با آبکاری گالوانیزه گرم ، ورق استیل و آلومینیوم به همراه کلیه اتصالات

- انواع وایر مش انواع وایر مش ساخته شده بصورت آبکاری گالوانیزه گرم و استیل

- طراحی و ساخت انواع ساپورت جهت نصب انواع سینی و نردبان کابل لوله های فولادی برق با سایزهای اینچ میلیمتر و پی جی به همراه کلیه اتصالات مربوطه شامل پایه های ساپورت ، سی ریل های مختلف ، رول بولت ، بستهای چنگالی

- انواع جعبه های تقسیم آلومینیومی دایکاست دیواره بلند در سایزهای مختلف با درجه

- انواع جعبه های تقسیم پی وی سی در سایزهای مختلف انواع بستهای چنگالی یک تکه و دو تکه جهت نردبان کابل ، لوله های فولادی برق با سایزهای اینچ ، میلیمتر و پی جی ( به زودی )

- انواع سان شید (سایه بان) انواع سان شید (سایه بان) جهت تابلو برق و جعبه های تقسیم

- انواع لوله های فولادی برق انواع لوله های فولادی برق در سایزهای میلیمتر ، اینچ و پی جی به صورت گالوانیزه گرم ، گالوانیزه سرد و مشکی مطابق با استاندارد های روز دنیا مانند ASTM , IEC , DIN

- انواع بستهای کابل و لوله فولادی انواع بستهای کابل و لوله فولادی پلی کربنات و پلی امید

فارسی

فارسی